Pallets

Pallets aren't just pieces of wood nailed together, they are a critical element of your product packaging and logistics.

Pallet Types

Although pallets come in all manner of sizes and configurations, all pallets fall into two very broad categories “Stringer” Pallets and Block Pallets.

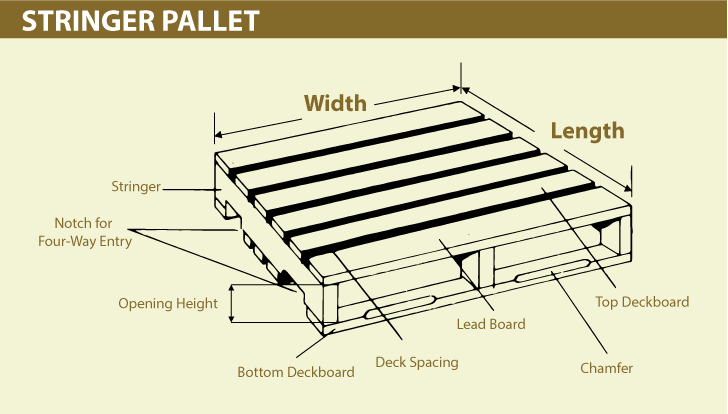

A stringer pallet uses “runners” or “stringers,” to support the unit load. The stringers are the boards, typically 2 x 4’s or 3 x 4’s, sandwiched between the top and bottom deck boards.

When specifying a stringer pallet, the length (i.e. the length of the stringer) is noted first, and the width or length of the deck boards is noted second. Stringers may be notched to allow for partial four-way fork entry, thus creating a “4-way” stringer pallet. If the stringers are not notched, it is called a “2-way” pallet, with fork entry only from either end.

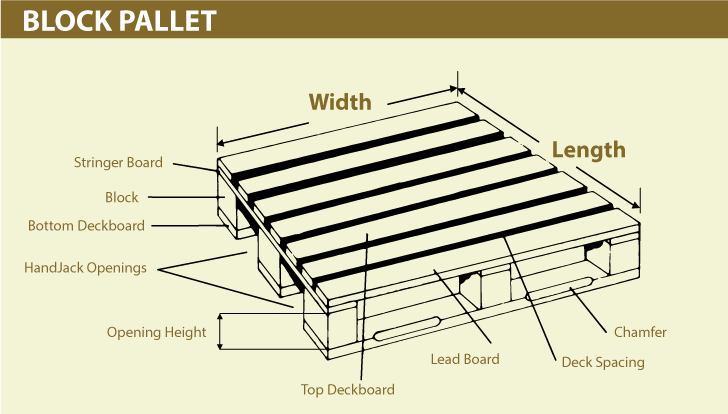

Block pallets are true 4-way entry pallets. They use blocks of solid wood, plywood, or plastic to support the unit load. Between the blocks and the deck boards are thin stringers, which form a mat with the deck board. The length of a block pallet is specified by the length of the stringer board and the width by the length of the deck boards. Block pallets can be designed with or without bottom deck boards, or a full-perimeter base.

Treated Pallets

This service includes pallets that are Heat Treated ISPM-15, Chemically Pressured and Fumigated.

Mun-Chin is fully licensed and certified to meet and exceed the strictest international heat-treatment standards (ISPM-15). This guarantees the safety and freedom of your shipment to move across any international border without delay.

Materials

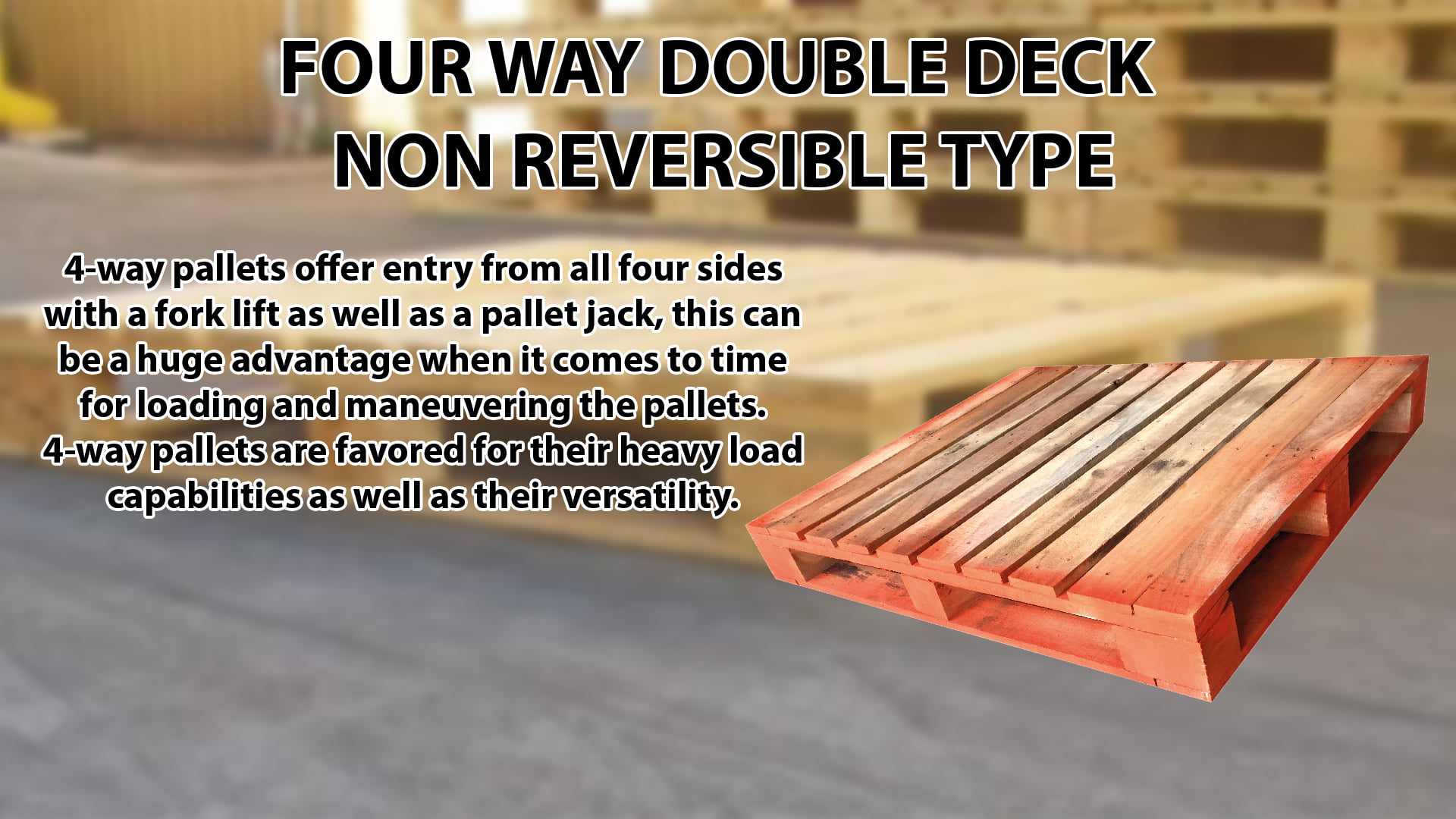

The least expensive pallets are made of softwood and are often considered expendable, to be discarded as trash, along with other wrapping elements, upon reaching their destination. These pallets are of very simple construction that permits lifting from one of two opposite positions only. Slightly more complex hardwood pallets plastic pallets and metal pallets can be lifted from all four sides.

These costlier pallets usually require a deposit and are returned to the sender or resold as used pallets. Many of these “four-way” pallets are color coded according to the loads they can bear, and other attributes.

Contact us for a free Pallet quote

Common Pallets and how they come in handy!

- Pallets allow a company to use air space in addition to floor space, reducing warehousing costs.

- Pallets reduce handling time with a savings in man hours and a decrease in overtime wages.

- Damage to goods may be totally eliminated with the installation of a palletization program.

- Savings from palletization average from 40 to 45 percent, with a range between 25 percent and as high as 80 percent.

- Mechanical material handling helps to cut down on personnel accidents often found with manual handling and lifting.

- Pilferage is reduced when individual items are strapped or wrapped to pallets in unitized bonded loads.

- The stringer pallet is the most commonly used pallet in the United States, with the most common size being 48 x 40″. The Grocery Manufacturer Association (GMA) has created a standard 48 x 40 hardwood stringer pallet specification that is used widely for many consumer products.